The Shocking Truth About Buying Used CNC Machines – Eagle Machine Tools Explains!

November 25, 2024

Eagle Machine Tools: The Secret to Superior CNC Machinery at Unbeatable Prices!

December 15, 2024Introduction

In the fast-evolving world of manufacturing, CNC (Computer Numerical Control) machines are playing a pivotal role in reshaping the future of Pakistan’s industries. With their ability to automate complex processes, CNC machines provide a significant edge in terms of precision, efficiency, and scalability. This article delves into how CNC technology is driving innovation across various sectors in Pakistan and why its adoption is critical for the country’s economic growth.

The Rise of CNC Machines in Pakistan

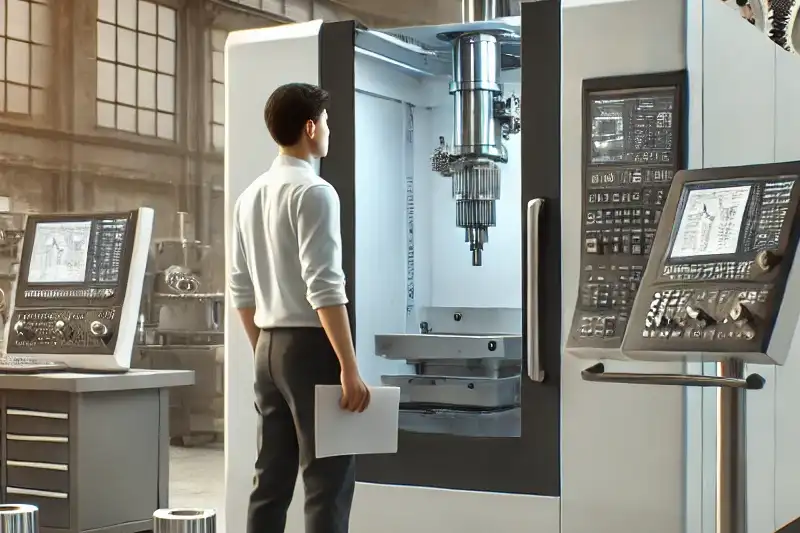

1. Driving Precision in Manufacturing

CNC machines are known for their ability to deliver unmatched precision. In industries where millimeter-level accuracy is crucial, such as aerospace and defense, CNC technology ensures that every product meets exact specifications. This level of precision not only enhances product quality but also minimizes waste and rework, resulting in cost savings for manufacturers.

2. Accelerating Production Timelines

With CNC machines, production processes that once took days or weeks can now be completed in hours. Automated operations allow manufacturers to handle large volumes without compromising on quality. This speed-to-market capability is particularly beneficial for Pakistan’s growing export sectors, such as textiles and surgical instruments, where timely delivery is essential to staying competitive globally.

3. Enabling Customization and Innovation

CNC machines empower manufacturers to create highly customized products without the need for extensive retooling. This flexibility opens up new avenues for innovation, enabling companies to offer unique solutions tailored to specific customer needs. For instance, in the medical device industry, CNC technology allows for the production of bespoke implants and instruments that cater to individual patient requirements.

Key Sectors Benefiting from CNC Technology in Pakistan

1. Precision Engineering: Tools and Dies

The tools and dies sector is one of the key beneficiaries of CNC machines in Pakistan. This industry requires high levels of precision to manufacture molds, dies, and fixtures used in various production processes. CNC machines help achieve exact dimensions and flawless finishes, reducing lead times and ensuring consistent quality.

2. Construction and Heavy Machinery

In the construction industry, CNC machines are used to fabricate metal parts for heavy machinery and equipment. The technology enables manufacturers to produce durable, high-strength components that can withstand the rigors of construction work. This not only improves the quality of the equipment but also enhances safety on construction sites.

3. Electronics and Appliances

CNC machines are crucial in the electronics industry for producing intricate components like printed circuit boards (PCBs), casings, and connectors. The high precision and repeatability of CNC machining ensure that electronic devices meet the stringent standards required in both local and international markets.

Case Study: Eagle Machine Tools – Leading the CNC Revolution in Pakistan

Eagle Machine Tools has emerged as a key player in making CNC technology accessible to Pakistani manufacturers. Based in Lahore, they offer a wide range of high-quality CNC machines, including lathes, milling machines, and vertical machining centers. Their commitment to customer satisfaction is evident through their comprehensive after-sales support, expert consultation, and ongoing training programs. To explore their offerings, visit https://eaglemachinetools.com.pk/.

Challenges to Wider CNC Machine Adoption in Pakistan

1. High Initial Investment

The cost of acquiring CNC machines can be a significant barrier for many small and medium-sized enterprises (SMEs). Solutions such as leasing options, low-interest loans, and government incentives could help mitigate this challenge.

2. Limited Awareness and Training

Many manufacturers in Pakistan still lack awareness about the benefits of CNC machines and the training required to operate them effectively. To address this, there is a need for more educational programs, workshops, and partnerships with local machine suppliers.

3. Infrastructure and Power Supply Issues

Frequent power outages and lack of infrastructure can hinder the optimal performance of CNC machines. Investments in stable power supply and industrial infrastructure will be crucial to support the growth of CNC technology.

Future Prospects of CNC Machines in Pakistan

The future for CNC machines in Pakistan looks bright. As more industries recognize the benefits of this technology, its adoption is expected to grow, leading to increased productivity, reduced costs, and enhanced global competitiveness. Companies like Eagle Machine Tools are at the forefront of this shift, providing the necessary tools and support to empower local manufacturers.

FAQs About CNC Machines in Pakistan

1. What are the main advantages of CNC machines?

CNC machines offer high precision, efficiency, scalability, and the ability to handle complex tasks, reducing manual intervention and errors.

2. How do CNC machines benefit Pakistan’s industries?

They enhance productivity, reduce costs, enable innovation, and help meet international quality standards, benefiting sectors like automotive, electronics, and medical devices.

3. What are the primary challenges in adopting CNC technology in Pakistan?

High initial costs, lack of skilled labor, and infrastructure issues are the main challenges facing the adoption of CNC technology in Pakistan.

4. How can companies finance CNC machines?

Companies can explore government subsidies, leasing options, and low-interest loans to finance their CNC machine purchases.

5. Where can Pakistani manufacturers buy high-quality CNC machines?

Eagle Machine Tools is a leading supplier of CNC machines in Pakistan. Visit https://eaglemachinetools.com.pk/ for more information.