Why CNC Machines Are Revolutionizing Pakistan’s Manufacturing Industry

August 30, 2024

How CNC Machines Are Transforming Pakistan’s Industrial Landscape

October 5, 2024Introduction

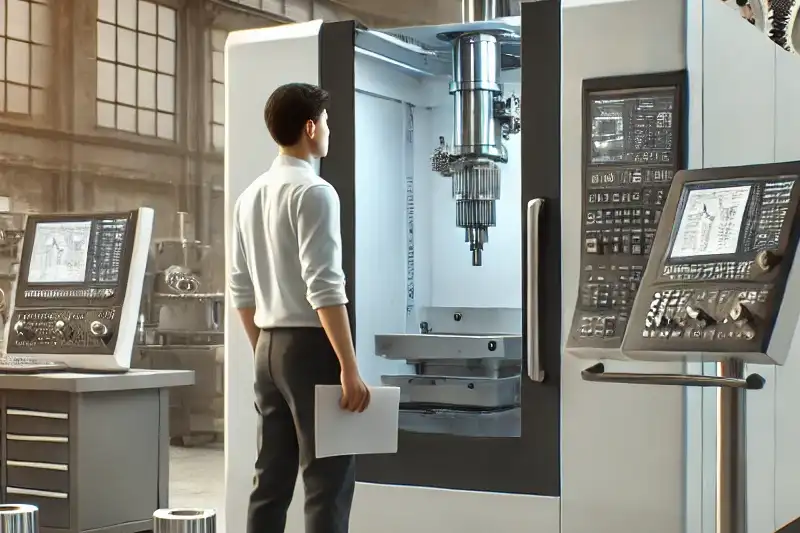

Pakistan’s manufacturing industry is undergoing a significant transformation, thanks to the adoption of CNC (Computer Numerical Control) machines. These high-tech tools are revolutionizing various sectors, from automotive to medical equipment, by offering precision, speed, and efficiency. In this article, we delve into how CNC machines are shaping the future of manufacturing in Pakistan and the opportunities they bring for local businesses.

The Rise of CNC Machines in Pakistan

Over the past decade, CNC machines have seen a surge in demand across Pakistan’s industrial landscape. As businesses strive to compete globally, the need for high-quality, precise, and efficient manufacturing processes has never been more crucial. CNC machines, with their ability to automate complex tasks, provide the perfect solution.

Advantages of CNC Machines for Pakistani Industries

1. Precision and Accuracy

CNC machines ensure high levels of precision and accuracy in manufacturing, reducing human error and improving product quality. This is particularly beneficial in industries where exact measurements are crucial, such as in the production of surgical instruments or aerospace components.

2. Enhanced Production Speed

Automated CNC machines drastically cut down production times by working continuously without fatigue. This leads to faster turnarounds, higher output, and the ability to meet tight deadlines—vital factors for staying competitive in the global market.

3. Cost-Effectiveness

While the initial investment in CNC machinery might be substantial, the long-term savings are significant. Reduced waste, fewer errors, and lower labor costs contribute to overall cost-effectiveness, making CNC machines a smart investment for businesses of all sizes.

4. Versatility Across Industries

CNC machines are versatile and can be used to produce a wide range of products, from car parts and agricultural tools to furniture and electronic components. This adaptability makes them suitable for numerous industries, expanding their market potential.

Case Studies: Successful CNC Machine Implementations in Pakistan

1. Automotive Sector: Precision Parts Manufacturing

Many automotive parts manufacturers in Pakistan, such as Millat Tractors and Honda Atlas, have integrated CNC machines into their production lines to achieve precision in components like engine parts and transmission systems. This has not only improved the quality of locally produced parts but also opened up export opportunities.

2. Medical Equipment: High-Quality Surgical Instruments

Companies in Sialkot, known for their surgical instrument manufacturing, use CNC machines to meet international standards. These machines provide the accuracy needed for intricate tools used in surgeries, making Pakistan a key exporter in the global medical equipment market.

3. Agricultural Industry: Efficient and Durable Tools

Pakistan’s agricultural sector benefits from CNC machines to produce durable and efficient equipment like plows, seeders, and harvesters. Local manufacturers like Al-Ghazi Tractors are utilizing CNC technology to meet the increasing demand for high-quality farming tools.

Challenges in the Adoption of CNC Machines

Despite the numerous benefits, the widespread adoption of CNC machines in Pakistan faces some challenges:

- High Initial Costs: The upfront investment for purchasing CNC machines can be a deterrent, especially for small and medium-sized enterprises (SMEs).

- Skill Gap: There is a shortage of trained operators and technicians who can efficiently manage and maintain CNC machines.

- Infrastructure Limitations: Inadequate infrastructure, such as inconsistent power supply, can hamper the effective utilization of CNC machines.

The Future of CNC Machines in Pakistan

As Pakistan continues to modernize its manufacturing sector, the adoption of CNC machines is expected to grow. Government initiatives aimed at encouraging technological advancements and increasing exports will likely boost the demand for CNC technology. Furthermore, local suppliers like Eagle Machine Tools are helping bridge the gap by providing access to high-quality CNC machinery and support services. For more details, visit https://eaglemachinetools.com.pk/.

Frequently Asked Questions (FAQs)

1. What are CNC machines used for in Pakistan?

CNC machines are used in various industries, including automotive, medical equipment, and agriculture, to produce precision parts and tools.

2. Are CNC machines cost-effective for small businesses?

Yes, despite the high initial investment, CNC machines offer long-term savings through reduced waste, labor costs, and improved efficiency.

3. What challenges are faced in adopting CNC machines in Pakistan?

Key challenges include high initial costs, a lack of skilled operators, and inadequate infrastructure.

4. How can I get training to operate CNC machines?

Many technical institutes offer training programs, and local suppliers like Eagle Machine Tools can provide guidance or recommend resources.

5. Where can I purchase CNC machines in Pakistan?

CNC machines can be purchased from reliable suppliers like Eagle Machine Tools. Visit their website at https://eaglemachinetools.com.pk/ for more information.