Ikegai GENSIS 1208 – Precision CNC Turning Center for Industrial Applications

September 12, 2024

GEAR HOBBING MACHINE

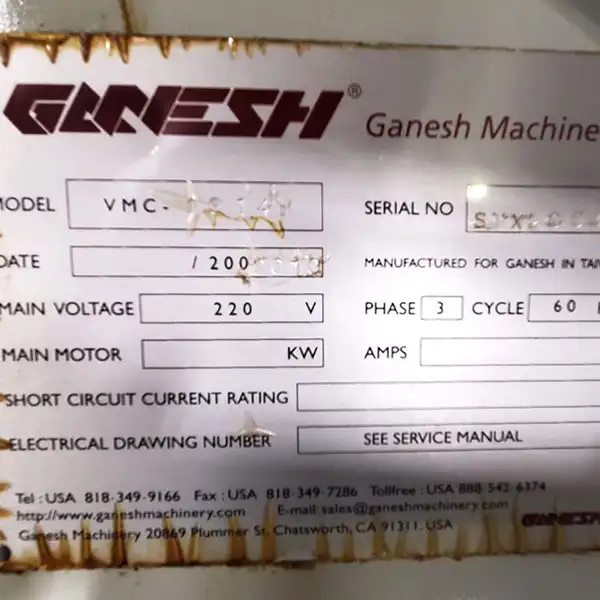

May 17, 2025Ganesh VMC-1814 – High-Performance Vertical Machining Center for Precision Manufacturing

The Ganesh VMC-1814 is a 2010 model vertical machining center offering superior precision, reliability, and efficiency. Perfect for complex machining tasks, this VMC enhances productivity in various industrial applications.

| CNC Machine Specifications | |

|---|---|

| Model | Ganesh VMC-1814 |

| Type | Vertical Machining Center |

| Year | 2010 |

| Spindle Speed | Up to 10,000 RPM |

| Spindle Motor Power | 20 HP |

| Table Size | 1800 mm x 1400 mm |

| X/Y/Z Travel | 1800 mm / 1400 mm / 800 mm |

| Tool Magazine Capacity | 24 Tools |

| Control System | Fanuc Oi-MC |

| Machine Weight | 15,000 kg |

Detailed Description

Introduction

The Ganesh VMC-1814 Vertical Machining Center is a powerhouse of precision and productivity, designed to meet the demands of modern manufacturing. With its advanced control systems, robust build, and versatile capabilities, this 2010 model is ideal for manufacturers seeking to enhance their machining operations across automotive, aerospace, and general engineering industries.

Key Features

- High-Speed Spindle for rapid and accurate machining operations.

- Rigid Construction reduces vibration, ensuring superior surface finish.

- Advanced CNC Control for easy programming and high-precision outputs.

- Large Work Envelope accommodates a wide range of part sizes.

- Efficient Chip Management System maintains a clean working environment.

- Automatic Tool Changer for reduced downtime and increased productivity.

Benefits

The Ganesh VMC-1814 offers exceptional accuracy and efficiency, making it a reliable choice for various machining tasks. Its high-speed spindle and robust design provide precise machining while minimizing downtime. The advanced CNC control system ensures ease of use, while the large work envelope and automatic tool changer enhance productivity, making it suitable for high-mix, low-volume production environments.

Usage Instructions

- Start-Up: Connect the machine to a stable power supply and power it on.

- Load Material: Place and secure the workpiece on the machine table using appropriate fixtures.

- Program Selection: Input or select the desired machining program on the CNC control panel.

- Begin Operation: Press the start button and monitor the machining process.

- Shutdown: Turn off the machine after completing the operation and clean the work area.

Care and Maintenance

- Regular Cleaning: Clear chips and debris from the table and internal areas after each use.

- Lubrication: Check and maintain lubrication levels in moving parts regularly.

- Tool Inspection: Regularly inspect and replace worn or damaged tools.

- Coolant Monitoring: Ensure coolant levels are adequate to prevent overheating.

- Scheduled Maintenance: Follow manufacturer guidelines for routine maintenance.

FAQs

Q1: What is the spindle speed of the Ganesh VMC-1814?

A1: The spindle speed goes up to 10,000 RPM.

Q2: Is this machine suitable for large workpieces?

A2: Yes, it has a large table size (1800 mm x 1400 mm) and a spacious work envelope for accommodating large parts.

Q3: How many tools can the automatic tool changer hold?

A3: The tool changer has a capacity of 24 tools.

Q4: What control system does it use?

A4: The machine is equipped with a Fanuc Oi-MC control system.

Q5: What is the power rating of the spindle motor?

A5: The spindle motor power is 20 HP.