CNC Vertical Machining Center Daewoo MYNX500 VMC with Fanuc Series 21M Control for Precision Manufacturing

September 9, 2024

Excel PMC-5T18 Vertical Machining Center – High-Precision CNC Machine for Industrial Use

September 12, 2024Ikegai CNC Turning Center TUR25 – High-Precision Turning for Industrial Applications

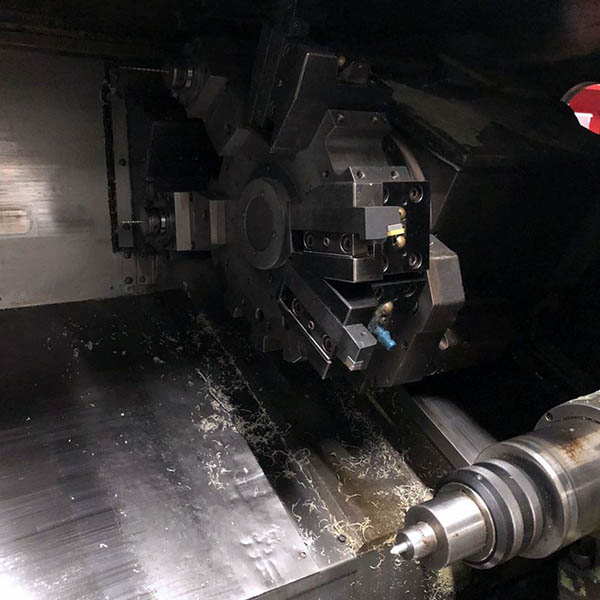

The Ikegai TUR25 CNC Turning Center is a robust and precise machine built for heavy-duty industrial turning applications. Featuring a 25 HP spindle and advanced Fanuc control, it ensures reliable, high-quality machining of complex parts.

| CNC Machine Specifications | |

|---|---|

| Swing Over Bed | 19.6" |

| Machining Length | 27.5" |

| Spindle Power | 25 HP |

| Spindle Speed (Max) | 3,150 RPM |

| Chuck Diameter | 10" |

| Tool Stations | 12 |

| X-axis Travel | 9.84" |

| Z-axis Travel | 27.5" |

| Control | Fanuc OT |

| Spindle Bore | 2.5" |

Detailed Description

Introduction

The Ikegai TUR25 CNC Turning Center is a high-performance industrial lathe designed for complex machining operations. Built with precision engineering and Japanese craftsmanship, this machine is ideal for industries requiring reliable, accurate, and consistent results in turning operations.

Key Features

- Powerful 25 HP Spindle: Delivers a maximum spindle speed of 3,150 RPM, enabling efficient cutting of tough materials.

- Fanuc CNC Control: Equipped with Fanuc OT control for high precision and user-friendly operation.

- 12-Station Turret: Allows quick tool changes and accommodates complex machining operations with both turning and milling capabilities.

- High Machining Capacity: Handles a swing over bed of 19.6″ and a maximum machining length of 27″.

- 360° C-axis Control: Provides flexibility for side drilling, tapping, and advanced multi-axis operations.

- Coolant & Chip Conveyor: Designed for continuous use with a built-in cooling system and chip removal conveyor to keep operations smooth and clean.

Benefits

The Ikegai TUR25 addresses the needs of industrial machinists looking for high precision and operational efficiency. The combination of a high-power spindle and versatile turret setup ensures fast cycle times and reduced downtime, helping businesses stay competitive. Its robust design minimizes vibration, allowing for accurate machining, even on tough materials.

Usage Instructions

- Initial Setup:

- Power on the machine and load the desired program via the Fanuc control panel.

- Secure your workpiece using the 10″ 3-jaw chuck.

- Tool Selection:

- Select the appropriate tool from the 12-station turret.

- Operation:

- Start the spindle and set the RPM to match your material’s requirements.

- Begin the turning process, monitoring spindle load and coolant flow.

- Post-Machining:

- Use the chip conveyor to remove debris.

- Inspect the finished product for accuracy.

Care and Maintenance

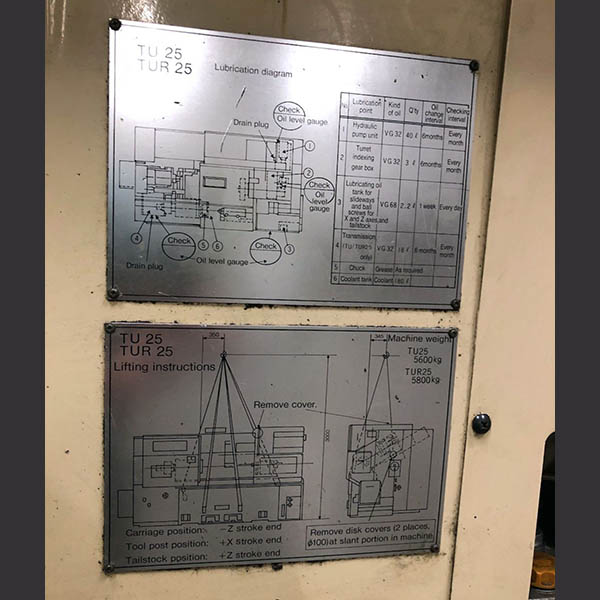

- Daily: Clean the machine bed and remove chips.

- Weekly: Check coolant levels and top up if necessary.

- Monthly: Lubricate all moving parts to prevent wear.

- Annually: Perform a full system check including calibration and software updates.

FAQs

Q: What is the maximum machining diameter?

A: The maximum machining diameter for the TUR25 is 18 inches.

Q: Does the machine support live tooling?

A: Yes, the Ikegai TUR25 supports live tooling for milling and drilling operations.

Q: What control system does it use?

A: The TUR25 comes with the Fanuc OT CNC control system.

Q: What is the power requirement?

A: The machine requires a 220V or 440V 3-phase power supply.

Q: Is the machine suitable for heavy materials?

A: Yes, with a 25 HP spindle, it is designed to handle tough materials and heavy-duty machining tasks.